Estimated Reading Time: 6 minutes

Estimated Reading Time: 12 minutes

Summary

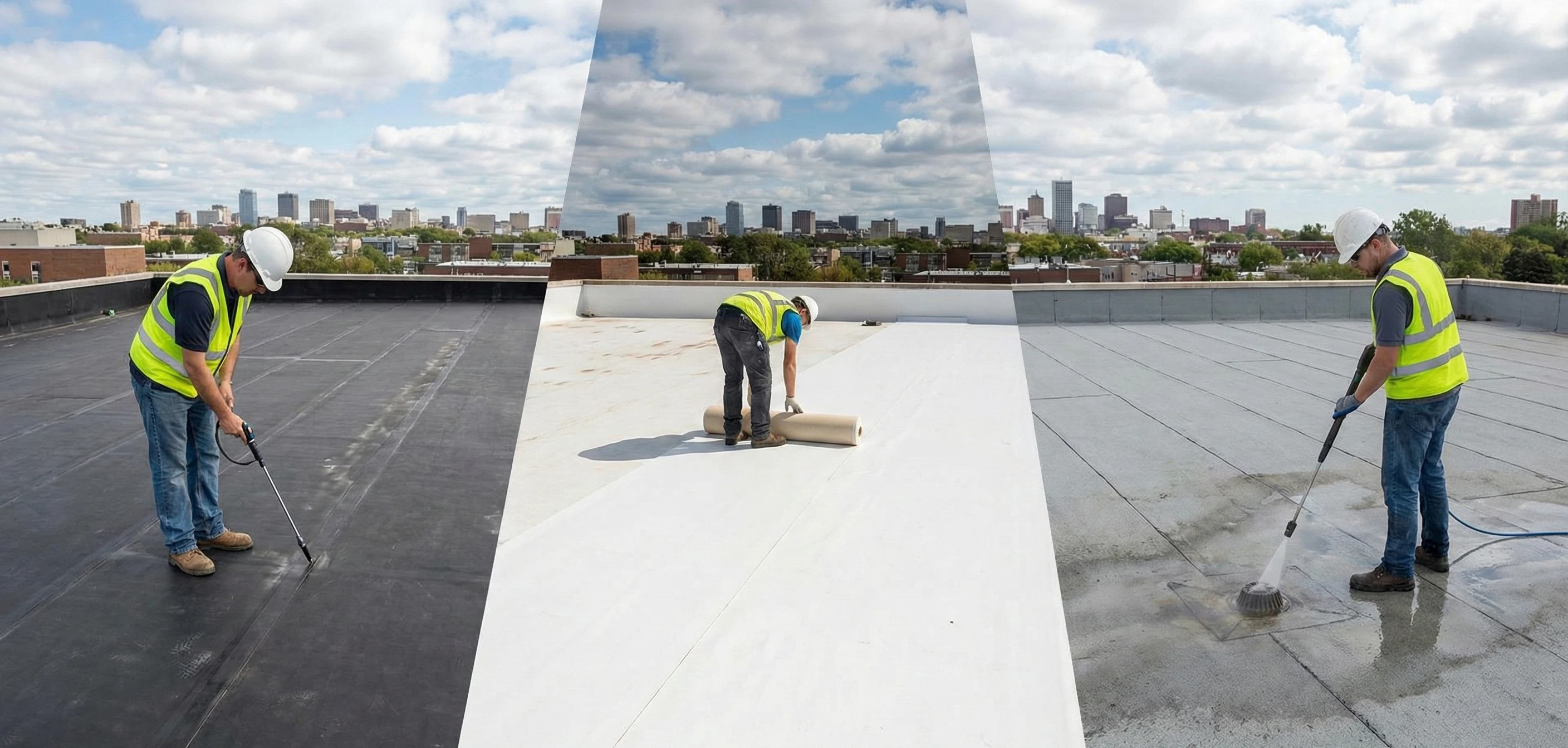

Choosing the right flat roofing material is one of the most important decisions a building owner can make. EPDM, TPO, and PVC are the three most common single-ply roofing systems used today—but each performs differently depending on your climate, building use, maintenance habits, and budget. This guide compares their lifespans, costs, strengths, weaknesses, and typical failure points to help you decide which system will last the longest and deliver the best value.

Main Points

EPDM, TPO, and PVC all offer long service lives, but each excels in different conditions.

EPDM lasts 20–30 years and works best in cold climates.

TPO also lasts around 20–30 years but performs best in hot, sunny regions.

PVC can exceed 30 years and handles chemicals, grease, and harsh environments extremely well.

Costs, maintenance needs, and durability vary significantly between the materials.

Improper installation is the top cause of early roof failure—no matter which material you choose.

When selecting a commercial flat roof, you’re doing more than choosing a material—you’re making a major investment that affects your building’s future maintenance costs, energy efficiency, and long-term durability. EPDM, TPO, and PVC are the three most common flat roof systems, and while they may look similar from a distance, they perform very differently.

If you're trying to decide which one lasts the longest—or which one is the best fit for your specific building—this guide breaks it all down in clear, simple terms.

Understanding What These Roofing Materials Are

Here’s a quick, easy-to-understand explanation of each material.

EPDM (Rubber Roofing)

EPDM is a heavy-duty rubber membrane. It’s known for:

Flexibility

UV resistance

Strong performance in cold climates

It’s been used for decades, which means there's a long track record of success.

TPO (Thermoplastic Polyolefin)

TPO is a bright-white, reflective roofing membrane. It’s popular because:

It reflects heat and lowers cooling costs

It’s lightweight

It’s affordable

Most newer warehouses and commercial buildings use TPO because of its energy efficiency.

PVC (Polyvinyl Chloride)

PVC is a strong, heat-welded membrane known for:

Chemical resistance

Long lifespan

Excellent waterproofing

It’s often used on restaurants, food processing buildings, and facilities with rooftop grease or harsh chemicals.

Lifespan Comparison: Which Lasts the Longest?

Commercial building owners often ask one key question: Which roof will last me the longest?

Here’s how the three materials compare.

EPDM Lifespan: 20–30 Years

Highly resistant to sun damage

Holds up well in cold climates

Known for long-term reliability

TPO Lifespan: 20–30 Years

Performs best when welded well and installed professionally

Lifespan varies by manufacturer (quality differences matter)

Good for hot climates

PVC Lifespan: 20–30+ Years

Very durable

Excellent chemical resistance

Strong seams that last decades

Lifespan Summary

EPDM → long and predictable life

TPO → long life but depends on welding quality

PVC → longest proven track record overall

Cost Per Square Foot: What Building Owners Can Expect

Costs vary by region, building size, and insulation, but here’s a simple breakdown:

EPDM Costs

Typically the least expensive option

Strong value for long lifespan

TPO Costs

Usually mid-range

Higher cost for thicker or premium versions

PVC Costs

Generally the highest upfront cost

Often worth it for buildings with chemicals, grease, or heavy foot traffic

Cost Overview

Lowest cost: EPDM

Mid-range: TPO

Highest cost: PVC

Climate Suitability: What Works Best Where?

No roofing material performs best in every climate. Here’s how they compare:

EPDM in Different Climates

Excellent in cold-weather regions

Handles freeze–thaw cycles without cracking

Dark surface absorbs heat → good in winter, less ideal in hot climates

TPO in Different Climates

Designed for hot, sunny areas

Reflective white surface reduces cooling costs

Older versions sometimes cracked in high heat—newer versions are improved

PVC in Different Climates

Strong in both hot and cold environments

Great for coastal buildings or areas with harsh weather

Performs exceptionally well where chemicals, grease, or industrial residue are present

Climate Summary

Cold climates → EPDM

Hot climates → TPO

Harsh or chemical-heavy climates → PVC

Maintenance Requirements: What Each System Needs

Each roofing type has different maintenance expectations.

EPDM Maintenance

Simple and predictable

Occasional seam checks

Monitor for punctures from tools or debris

TPO Maintenance

More dependent on seam quality

Watch for weak welds or surface cracking

Needs routine inspections for UV wear

PVC Maintenance

Generally low maintenance

Check seams and corners

Monitor areas near rooftop equipment

Maintenance Summary

EPDM → low-to-moderate maintenance

TPO → moderate maintenance (seams matter most)

PVC → low maintenance

Pros, Cons, and Common Failure Points

A head-to-head comparison helps clarify which system fits your needs.

EPDM Pros & Cons

Pros

Long lifespan

Performs in cold climates

Affordable

Easy to repair

Cons

Absorbs heat

Can be punctured more easily

Seams may weaken over time

Common Failure Points

Tool punctures

Shrinkage along edges

Aging adhesives in seams

TPO Pros & Cons

Pros

Highly reflective

Energy-efficient

Lightweight

Affordable

Cons

Performance varies by brand

Requires precise installation

Older versions were vulnerable to heat damage

Common Failure Points

Seams from improper welding

UV cracking

Installation errors

PVC Pros & Cons

Pros

Excellent chemical resistance

Long lifespan

Durable seams

Performs well in extreme conditions

Cons

Higher upfront cost

Can shrink slightly over time

Some lower-quality versions become brittle in extreme cold

Common Failure Points

Stress at corners

Expansion near rooftop equipment

How to Choose the Right Material for Your Building

Here are a few simple questions to help you decide:

1. What climate is your building in?

Cold → EPDM

Hot → TPO

Unpredictable or coastal → PVC

2. Do you have rooftop equipment?

PVC handles mechanical stress well.

3. Are there chemicals, grease, or restaurants in the building?

PVC is the safest choice.

4. Is energy efficiency a priority?

TPO offers excellent cooling performance.

5. What is your long-term budget?

EPDM gives strong lifespan at a lower cost.

Conclusion: So, Which Roof Lasts the Longest?

All three systems—EPDM, TPO, and PVC—can reach 20–30 years or more when installed and maintained properly. The real difference comes from choosing the material that fits your building’s specific needs.

Best overall durability: PVC

Best value for long life at a lower cost: EPDM

Best for hot climates and energy savings: TPO

If you're unsure which material is best for your building, a professional roofing inspection can give you personalized recommendations based on your climate, roof condition, and goals.